即将直播:midas MeshFree模具吊装工况分析(4月11日)

- 作者优秀

- 优秀教师/意见领袖/博士学历/特邀专家/独家讲师

- 平台推荐

- 内容稀缺

一、midas MeshFree模具吊装公开课

为了帮助用户掌握midas MeshFree摸具吊装工况分析能力,由仿真秀主办的2024年汽车设计仿真专题报告会第三期将邀请MIDAS IT中国区机械事业部仿真软件技术负责人梁华老师做《midas MeshFree模具吊装工况分析》,内容包括:midas MeshFree的开发背景、算法特点和功能优势;midas MeshFree材料、边界和荷载设置方法;midas MeshFree模具吊装分析要点和基本流程;结果趋势判断、误差分析和精度控制。以下是直播安排

2024汽车设计仿真(三)midas MeshFree模具吊装工况分析-仿真秀直播

扫码观看直播和回放

二、MeshFree in Toronto

MeshFree in Toronto (NUMISHEET2022)

Let's listen to it directly through Yoon Ki-hoon, Manager of the Kia Molding Technology Department, who contributed and presented the paper!!

I gave a presentation at a session on the topic of Multiscale modeling of deformation, and it was interesting to see 30-40 people from national and international universities as well as those in charge of numerical analysis and corporate representatives. Let me introduce you to the announcement。

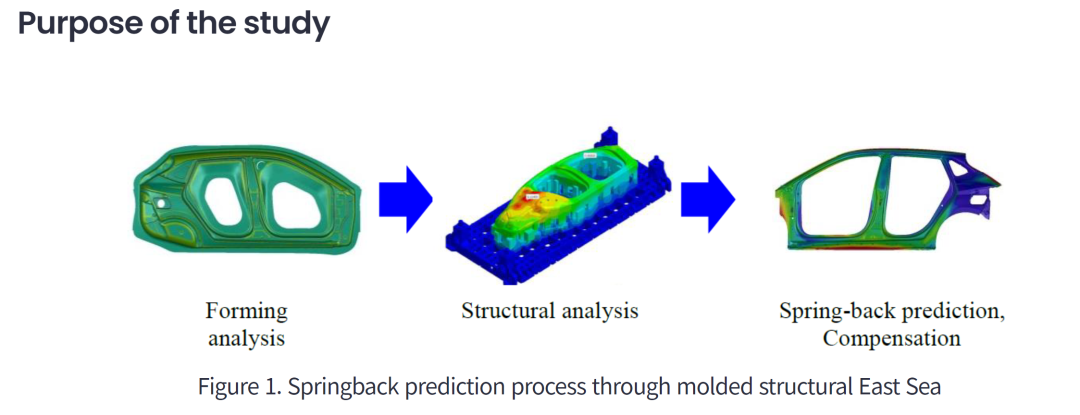

Recently, consumer car preferences have changed dramatically, accelerating plans to produce a variety of car models. For this reason, most automotive engineers are constantly called upon to develop new technologies that can reduce the time it takes to develop new models and produce customizations, and they want to introduce simultaneous engineering engineering into the new model development process.

Mold engineers are likewise attempting to shorten mold development time by eliminating additional calibration airborne. Usually in structural analysis, molds are considered rigid to simplify engineering difficulties. However, in practice, the panel forming force causes contact pressure on the mold shape surface, and that pressure causes elastic deformation in the mold.

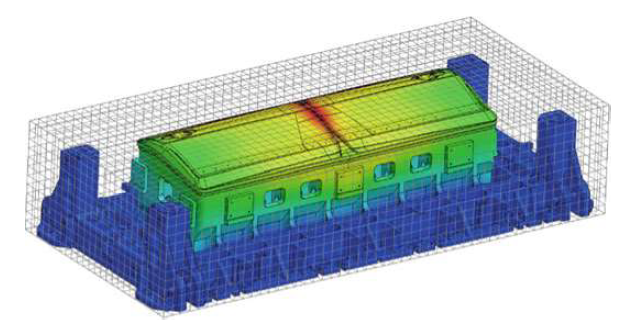

Figure 2. Mold model in which elastic deformation occurs

Figure 3. Structural analysis model of mold using midas MeshFree from IBM

Conclusion and future plans

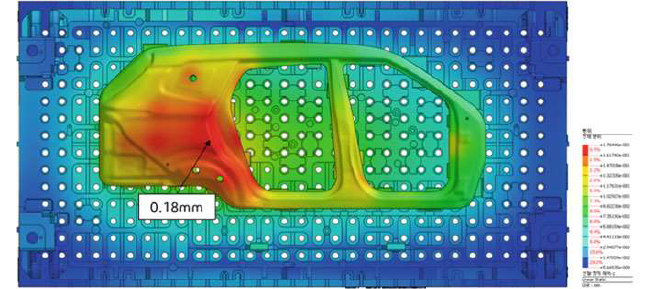

In this study, a molded-structural East Sea was applied to a press mold and the mold deformation distribution was obtained as a final analysis. The results of this analysis were found to be similar to the values measured in the actual mold.

Figure 5. Mold Deformation Analysis Results Using MeshFree-2

The improved process can be utilized practically in the mold design business without requiring FEM specific expertise. In particular, if a mold manufacturer needs a fast and accurate analysis, but it is difficult to hire an analysis expert, it seems to be a cost-effective method. In the future, this analysis process will be extended to all molds that are developed in the future.